Best Practices for Temperature-Controlled Transport

Temperature-controlled logistics are necessary for different food products, flowers, and produce. Shipping in a poorly managed cold chain with extra delays in the timeline or not giving importance to spoilage risk leads to severe problems that could even give you a loss in profit margins. If you want to know the best practices for such transportation, this is the right blog for you where you can maintain a strategic cold chain by mitigating such risks and taking better control over these outcomes.

1. Recruit A Knowledgeable Professional

Safe transportation can be ensured with the assistance of a well-qualified professional, whether an internal resource or an external vendor. Shippers and carriers have an essential relationship, and an expert may help them work through any issues in that partnership. Seek out professionals who can recognize ways to balance these attributes with strategic considerations that benefit the shipper and the carrier.

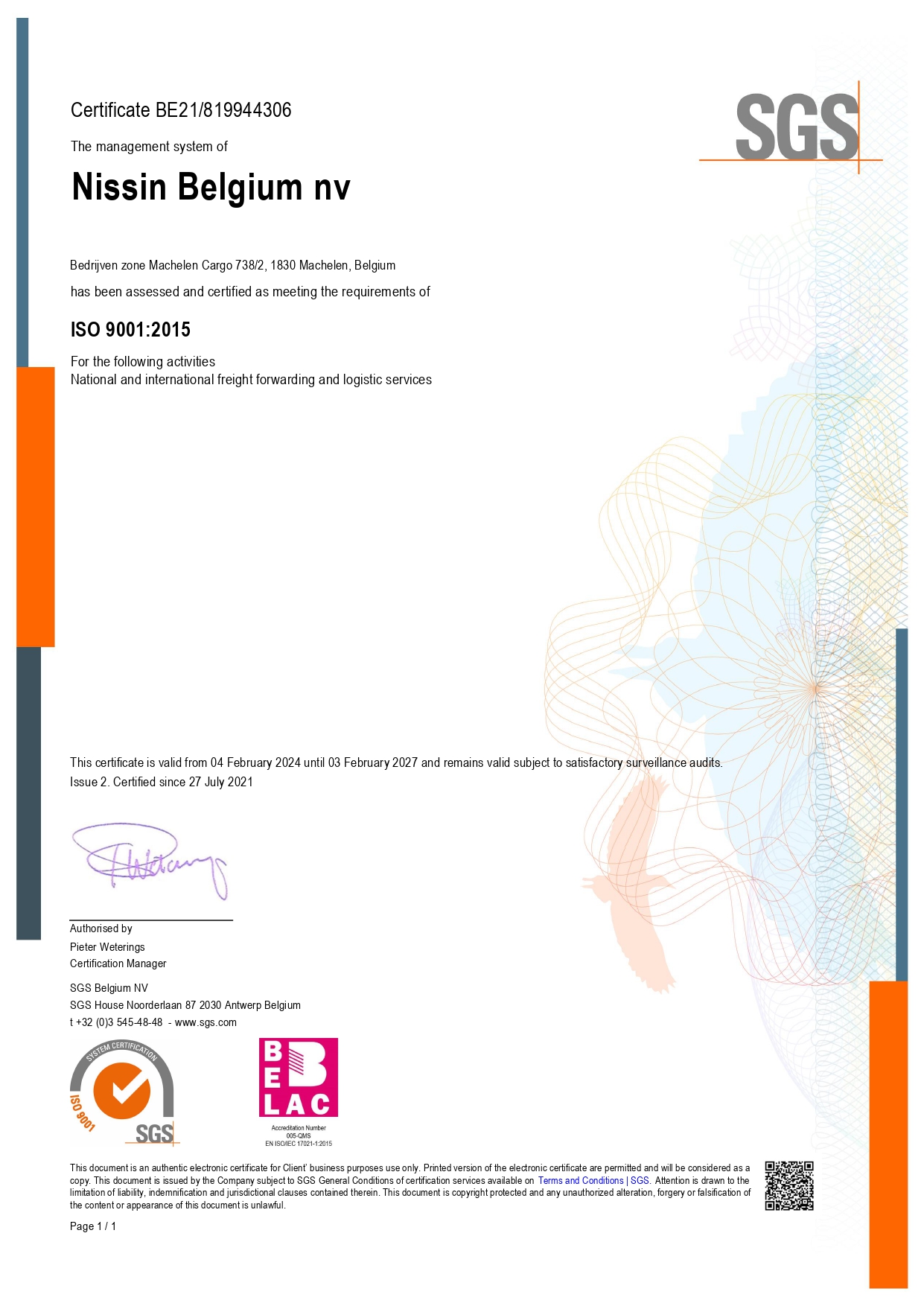

You can count on Nissin for temperature-controlled transit if you have trouble shipping. For each product, we select the best tools and equipment. You can rest assured that your items will arrive in perfect condition and on time.

2. Know the Capacity:

Whether your temperature-controlled transport is via road, air, sea, or rail, every service has its factors where you must know the price, along with pros and cons. For instance, some commodities of higher price points might benefit from expensive yet faster shipping options. Suppose a shipper transports an entire truckload of cheese to the local retailers. In that case, they might be able to have these carriers move empty cartons on the delivery and can help solve a reverse logistics problem. With such new and innovative planning, shippers can find a strong relationship and quickly get a suitable capacity.

3. Share Your Responsibilities:

The most crucial component of temperature-controlled transportation is loading and unloading. The shippers and carriers must also share responsibility for the loading dock temperature, the time it takes, and the weather conditions outside the loading dock. Consider the following crucial points:

- Confirm the temperature of the product

- Understand the condition of the equipment

- Proper checking of container airflow:

Before accepting the loads, carriers can check the temperature. If any product is set at the wrong temperature, it can be rejected.

Before loading the product, the shipper and carrier need a thorough inspection of equipment to verify whether it’s in good working order. Shippers can pay attention to even minor details like tears in chutes that could impact the effectiveness of the refrigerator.

Pallets are stacked to affect airflow, and blocked air might cause cold zones or hot spots. Shippers need to oversee the loading to ensure there is space for the passage of air between walls, floor, air chutes, pallets, and the ceiling.

For many types of cargo, a constant temperature is the most crucial aspect of a reliable and closed cold chain. When you want to meet regulations and preserve the quality of the product, maintaining temperature is vital. Nissin can help you with temperature-controlled transport effectively and without any worries.

Cost & Technology:

Temperature-controlled transport is advancing when you use tracing technology, move beyond the basic tracking, and use real-time monitoring for global cold chains. But technologies like GPS tracking or temperature sensors come at a high rate. Hence why you should optimize cost-effective and technological advances.

Nissin keeps better track of temperature to ensure better shipping. For more details, contact us now.