Preserving Pharmaceutical Integrity: Temperature Monitoring in Cold Chain Logistics

Pharmaceutical products move through some of the most controlled supply chains in the world. In pharma logistics, precision is not optional. It directly impacts drug stability, regulatory compliance, and ultimately patient outcomes.

Vaccines, biologics, injectables, and advanced therapies are highly temperature sensitive. From manufacturing plants to hospitals and pharmacies, these products must travel within tightly defined ranges. This is where structured Cold Chain Logistics and accurate temperature monitoring systems play a defining role in modern pharma and healthcare logistics.

Let’s take a closer look at how temperature control protects pharmaceutical integrity across the global supply chain.

Understanding Temperature Sensitivity in Pharmaceuticals

Many medicines are chemically complex and biologically active. Even small fluctuations outside approved temperature ranges can alter their composition. For example:

1. Refrigerated products often require storage between 2°C and 8°C

2. Certain vaccines demand ultra-low temperatures below minus 60°C

3. Controlled room temperature drugs must remain within strict ambient limits

A short exposure to higher or lower temperatures can reduce potency. In some cases, degradation is invisible and cannot be reversed. That makes preventive control far more important than post shipment testing.

In pharma logistics, every movement must account for environmental stability.

What Cold Chain Logistics Really Involves

Many assume Cold Chain Logistics simply means refrigerated trucks or storage rooms. In reality, it is a coordinated system that covers the entire lifecycle of temperature sensitive shipments.

A strong cold chain includes:

1. Qualified packaging solutions validated through thermal testing

2. Temperature controlled warehousing

3. Dedicated air freight handling procedures

4. Priority loading and unloading protocols

5. Trained personnel familiar with pharmaceutical handling

Every transfer point introduces potential risk. A shipment may move from a manufacturing site to a consolidation warehouse, then to an airport, onward to an international hub, and finally to local distribution. Each stage must maintain the required temperature range without interruption.

This layered coordination defines effective pharma and healthcare logistics.

Why Temperature Monitoring Is Non-Negotiable

Without reliable temperature monitoring, even the best cold chain design becomes guesswork.

Monitoring devices record environmental conditions throughout transit. These tools provide:

1. Continuous temperature data

2. Timestamped deviation alerts

3. GPS location tracking

4. Downloadable compliance reports

Real time visibility allows logistics teams to react immediately. If a shipment experiences unexpected delays or equipment malfunction, corrective action can be taken before product stability is compromised.

Instead of discovering issues after delivery, companies gain actionable insights during transit. That difference can protect both product value and patient safety.

Managing Global Transport Risks

Pharmaceutical supply chains are international. Products often cross multiple borders before reaching their destination. Global movement introduces variables such as:

1. Customs inspections

2. Airport congestion

3. Weather disruptions

4. Handling delays

5. Regulatory documentation checks

Each event can extend transit time. In temperature sensitive shipping, time is directly linked to stability risk.

Advanced Cold Chain Logistics planning combines:

1. Route validation studies

2. Buffer time calculations

3. Backup storage options at transit hubs

4. Coordinated airline partnerships

Clear escalation procedures

With robust temperature monitoring, teams can track exposure duration and make informed decisions if conditions shift.

Regulatory Pressure and Documentation

Pharmaceutical distribution is governed by strict Good Distribution Practice guidelines. Regulators expect companies to demonstrate full control over environmental conditions during transport.

Documentation requirements typically include:

1. Temperature mapping studies

2. Validated shipping configurations

3. Audit ready monitoring reports

4. Deviation investigation records

5. Corrective action documentation

Failure to comply can result in rejected shipments, financial penalties, and reputational damage.

In structured pharma logistics, compliance is built into daily operations rather than treated as an afterthought.

Financial Implications of Temperature Excursions

Pharmaceutical shipments often represent high value inventory. Specialty drugs and biologics can carry significant cost per pallet. A single rejected shipment can result in:

1. Direct product loss

2. Additional transportation expenses

3. Insurance claims

4. Delayed patient treatment

5. Contractual penalties

Beyond financial exposure, the reputational impact can be long lasting. Trust is critical in healthcare. Reliable pharma and healthcare logistics providers understand that precision protects more than inventory. It protects brand credibility.

Packaging Strategy and Thermal Stability

Effective cold chain performance begins with packaging design. Insulated containers, active temperature-controlled units, dry ice systems, and phase change materials all serve specific roles depending on product requirements.

Key considerations include:

1. Transit duration

2. External climate conditions

3. Mode of transport

4. Customs clearance timelines

5. Storage handoff intervals

Thermal packaging must be tested under real world scenarios. Once validated, integrated temperature monitoring devices confirm that the system performs as expected during live shipments.

Packaging and monitoring work together to form a complete protective solution.

Building a Resilient Pharma Supply Chain

The pharmaceutical industry continues to evolve. Cell and gene therapies, personalized medicines and biologics are becoming more common. These products often demand tighter temperature tolerances and faster delivery windows.

As complexity grows, so does the importance of reliable Cold Chain Logistics infrastructure. Digital visibility platforms, automated reporting systems, and integrated logistics networks allow manufacturers to maintain greater oversight.

Resilience in pharma logistics means:

1. Anticipating disruption

2. Maintaining transparent data flow

3. Working with experienced life sciences specialists

4. Continuously refining validated transport lanes

With proactive planning, temperature control becomes a predictable process rather than a reactive challenge.

Work with a Trusted Life Sciences Logistics Partner

Protecting pharmaceutical integrity requires discipline, expertise, and operational control at every stage of transit.

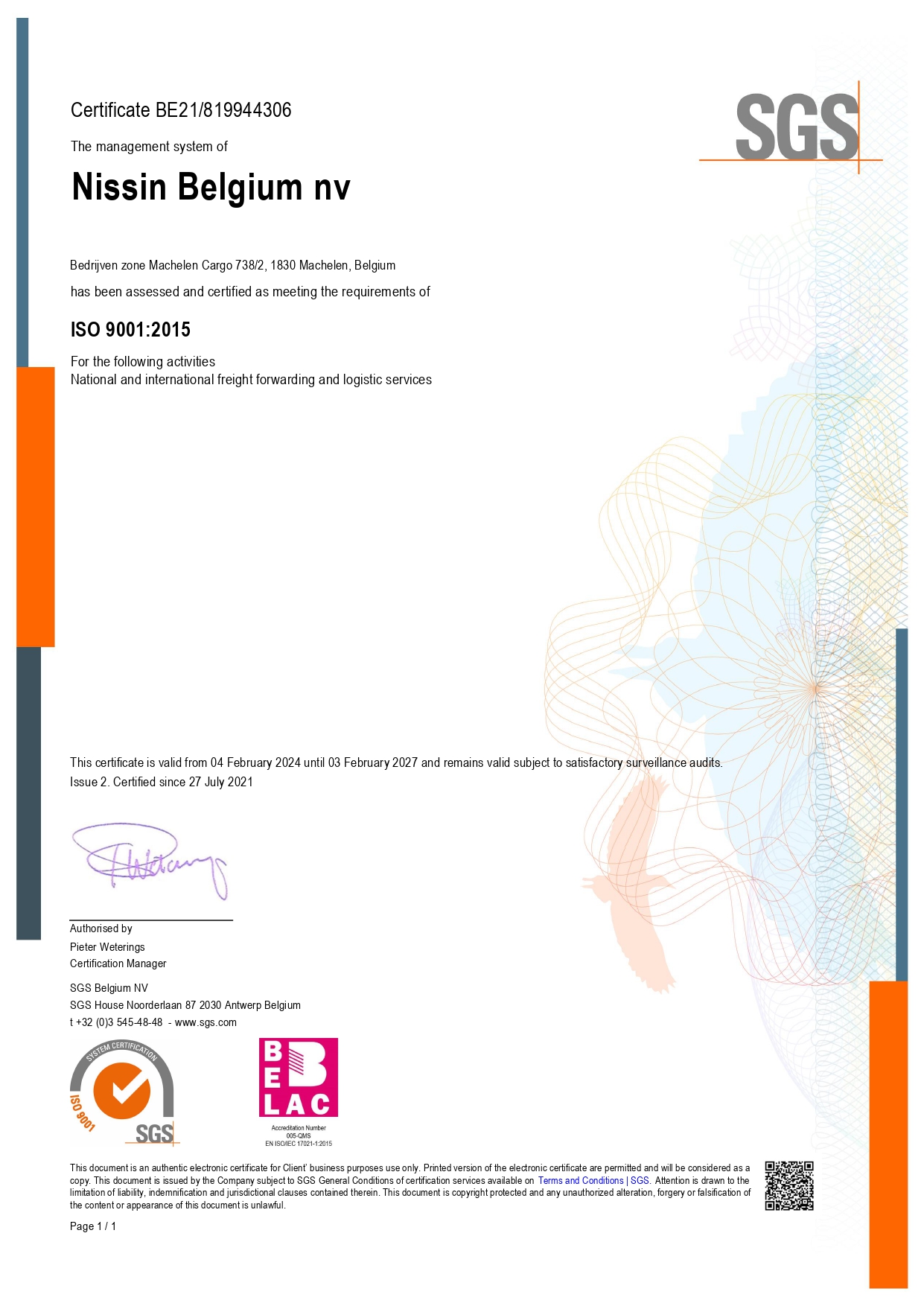

Nissin Belgium provides structured pharma and healthcare logistics solutions supported by validated Cold Chain Logistics systems and advanced temperature monitoring technology. From secure warehousing to global air freight coordination, shipments are managed with regulatory awareness and data driven oversight.

Our team is ready to assist you. Please call us at +32 2 751 44 99 or email your requirements to HowCanIHelpYou@be.nissin-eu.com for prompt and professional support.