Impact of Digitalization on Life Sciences Logistics: From Tracking to Transparency

In the world of life sciences, logistics is more than just transportation. It’s about safeguarding critical products vaccines, biologics, temperature-sensitive medications from origin to end-user. As the industry grows more complex, digitalization is changing the way logistics services operate. It’s no longer just about moving goods quickly. It’s about precision, visibility, and trust.

Let’s unpack how digital tools are reshaping the entire chain from pharma logistics to freight forwarding, from warehousing to air shipping, and how it’s driving a new era of accountability.

Real-Time Visibility is Now the Baseline

Not long ago, tracking shipments in pharma meant hoping a pallet reached its destination on time maybe with a scanned update at a hub in between. Now, shippers and stakeholders expect constant visibility.

With digital tools like GPS-enabled tracking, RFID, and IoT sensors, pharma companies can follow every box of medication as it moves across continents. From departure to arrival, logistics services providers can track not just location, but temperature, humidity, light exposure, and shock events in real time. That data is stored and shared through secure dashboards or mobile alerts giving supply chain teams confidence and control.

This is especially critical for temperature controlled freight, where a single degree of deviation can compromise the integrity of a shipment. In digitalized logistics, alerts trigger the moment a reading veers outside set thresholds, allowing fast response before damage occurs.

Pharma Logistics Demands Full Traceability

In pharma logistics, traceability is non-negotiable. Regulators and quality standards require not only that products arrive intact, but that every stop, condition, and transfer is recorded. That’s where digitalization steps in.

Electronic documentation, block-chain secured records, and cloud-based platforms now allow every stakeholder manufacturer, 3PL, carrier, regulatory body to access a single, secure chain of records. The chain of custody becomes transparent, audit-ready, and verifiable. If a temperature spike or delay occurs, it’s traceable down to the minute, with accountability clear at each link.

For complex cold-chain lanes spanning continents often involving air shipping, ground transfer, and freight forwarding this traceability is invaluable. It keeps delays from snowballing and reduces the risk of waste or non-compliance.

Smarter Warehousing and Inventory Management

Warehousing in the life sciences sector has its own challenges. Temperature zones, special handling procedures, regulatory inspections, and expiry tracking all factor in. With digitalization, warehouses have moved far beyond manual logs and Excel sheets.

Temperature sensors continuously monitor climate conditions and feed live data to centralized systems. Automated inventory software tracks stock levels and expiration dates in real-time. Robotics and smart shelving optimize space and reduce human error.

This automation reduces spoilage and improves efficiency but more importantly, it keeps vital products like vaccines or biologics available when patients need them.

Predictive Logistics and Risk Management

One of the most impactful shifts from digitalization is the move from reactive to predictive logistics services. It’s no longer just about fixing problems it’s about anticipating them.

Machine learning and analytics are now used to identify patterns that may lead to risk. For example: if a particular freight forwarding route has a history of customs delays, or if a specific carrier often encounters temperature excursions during transit, systems can flag this before the next shipment is dispatched. Logistics managers can reroute, adjust packaging, or assign alternate carriers cutting down the chance of loss.

Predictive analytics can also help companies forecast demand more accurately, reducing the need for overstock and last-minute shipments.

Digitalization Supports Sustainability Goals

Life sciences companies are under growing pressure to reduce waste and operate sustainably. Digital logistics supports that too.

Precise route planning reduces unnecessary fuel consumption. Smart packaging solutions track environmental performance, so insulation and cooling elements are used more efficiently. Data-driven warehousing helps companies optimize inventory reducing expired stock and last-minute air freight, which has a higher carbon footprint than other modes.

By identifying inefficiencies and preventing loss, digital logistics services contribute directly to reducing environmental impact.

Trust and Compliance Built Into the System

Digitalization also simplifies compliance. Instead of chasing paperwork during audits or recalls, companies can access records instantly from shipping logs to warehouse climate data. Automated systems reduce manual errors and provide consistent reporting across the supply chain.

This builds trust not just with regulators, but with patients and healthcare providers too. In an industry where product integrity can mean life or death, that trust matters.

Why It Matters Now

The demand for digital transparency in pharma logistics isn’t just a nice-to-have anymore. It’s fast becoming the industry standard. Regulatory requirements are rising. Biologic drugs are more temperature-sensitive. Global supply chains are under more pressure than ever. And patient expectations for speed, safety, and reliability continue to grow.

Digitalization is the only path forward that can keep up.

Nissin’s Role in the Future of Life Sciences Logistics

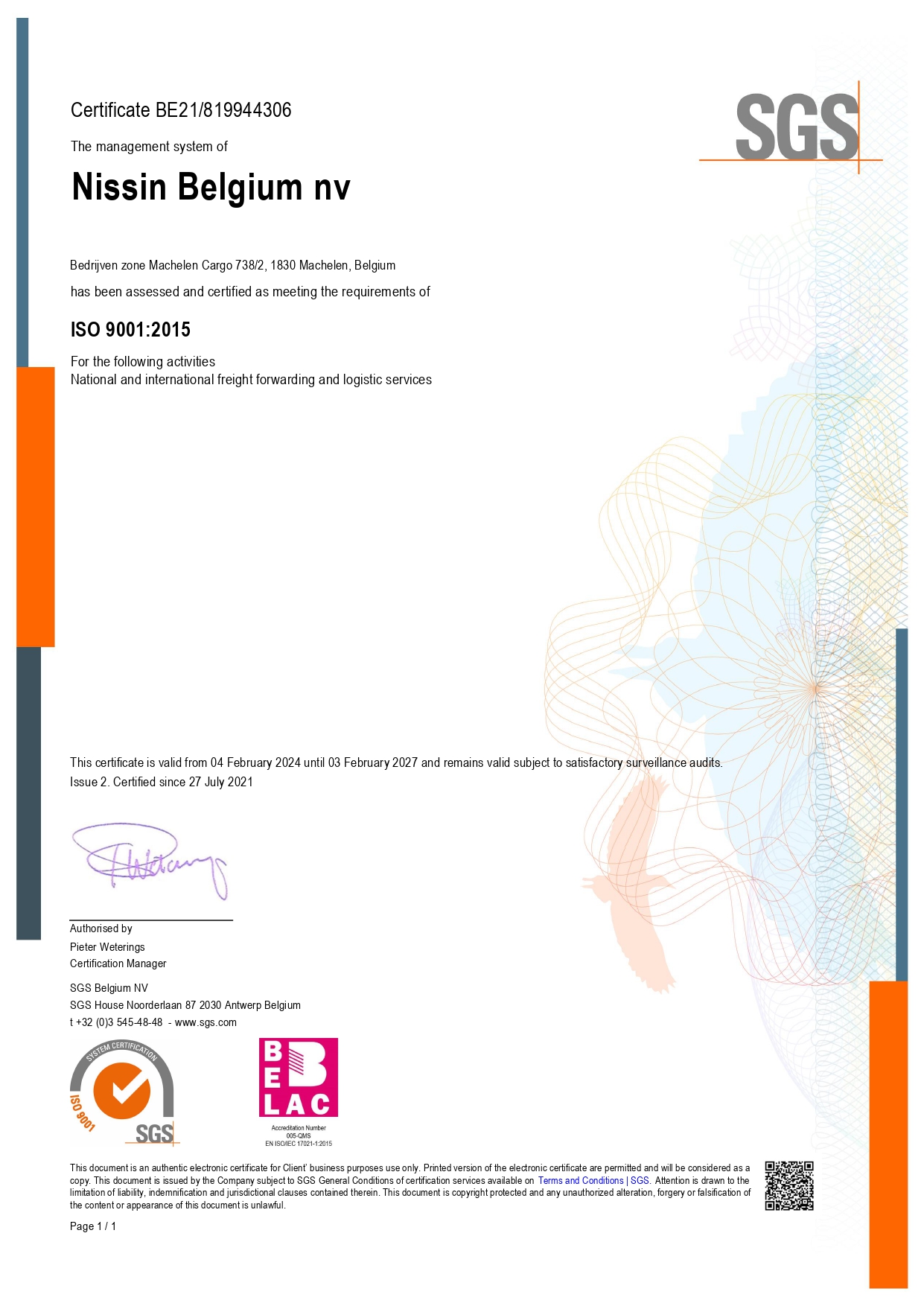

At Nissin Belgium, we’ve built our LifeLink360 platform around the realities of pharmaceutical transport. From real-time tracking to secure document sharing and cold chain compliance, our technology is built to support the life sciences industry’s unique needs.

Our air shipping and freight forwarding services are integrated with smart monitoring and quality control systems. Our warehousing solutions support ambient, cold, and ultra-cold zones with precision. And our team stays aligned with global Good Distribution Practice (GDP) guidelines at every step.

We don’t just move products. We move data, trust, and accountability across borders and across your supply chain.

Talk to Us

Digitalization isn’t just changing logistics it’s raising the bar. If your pharmaceutical or biotech supply chain needs smarter visibility, better cold chain control, or more agile logistics services, Nissin Belgium is ready to help.

Explore how LifeLink360 can support your pharma supply chain needs today. Need a specific solution? Our team is ready to assist you please call us at +32 2 751 44 99 or email your requirements to HowCanIHelpYou@be.nissin-eu.com for prompt and professional support.