How Do Refrigerated Shipping Containers Work?

If you’ve ever wondered how fresh salmon from Norway or tropical fruit from Ecuador makes it to Europe in perfect condition, the answer lies in reefer containers. These temperature-controlled shipping units are the quiet heroes of global trade, keeping goods fresh across oceans and climates. Let’s look closer at how reefer containers work, why they matter, and how logistics companies like Nissin Belgium keep the cold chain running smoothly.

What Are Reefer Containers?

Reefer containers (short for refrigerated containers) are mobile, insulated chambers fitted with a built-in cooling system. They look like standard shipping containers but are far more advanced inside.

Each refrigerated reefer container can maintain temperatures anywhere between -30°C and +30°C, depending on the product. That flexibility means they can carry frozen meat, seafood, fresh produce, dairy, pharmaceuticals, and even flowers.

Think of them as portable refrigerators that never take a break. Once plugged into an electric source on a ship, truck, or at a terminal, they work continuously to keep your goods at the perfect temperature.

How Do Reefer Containers Work?

Here’s the thing: reefers don’t just make things cold; they control the environment. Inside each container is a closed-loop air system that constantly circulates chilled air to maintain even temperatures throughout.

Here’s how it works step-by-step.

1. The Cooling Process

Warm air inside the container gets pulled into the refrigeration unit, where it passes over evaporator coils filled with refrigerant gas. The heat is absorbed and expelled outside, while the cooled air is pushed back through vents at the floor. This creates a steady stream of cold air circulating around the cargo like a gentle, continuous breeze that never stops.

That consistency is what keeps ice cream frozen solid and tropical fruit fresh all the way to its destination.

2. Smart Airflow Design

The container floor has a T-shaped pattern that allows air to flow freely under and around the cargo. This design prevents hot pockets that could ruin delicate items. To work properly, cargo must be stacked carefully, leaving space for airflow.

When loaded correctly, every corner of the reefer stays at the same temperature with no warm spots and no spoilage.

3. Temperature and Humidity Control

Modern reefer containers come with precise digital controls that let operators set temperature and humidity to the decimal. For example, pharmaceutical shipments might require +5°C, while avocados need a gradual cooling curve to slow ripening.

Humidity levels can also be adjusted to prevent dehydration or excess moisture. Too much humidity can cause mold, while too little can dry out produce. These containers balance both automatically with sensors that continuously monitor conditions.

Types of Reefer Containers

There isn’t a single design that fits all needs. Different industries rely on specific types of reefer containers depending on their cargo requirements.

1. Closed Reefer

The standard workhorse. It’s a fully integrated, insulated container with a self-powered refrigeration unit. Perfect for frozen foods, meat, and pharmaceuticals.

2. Controlled Atmosphere Reefer

Ideal for fresh produce, seafood, and flowers. These containers not only control temperature and humidity but also regulate oxygen and carbon dioxide levels to slow down the natural aging process of products.

3. AFAM Reefer (Automatic Fresh Air Management)

A newer generation container that automatically adjusts air intake to match cargo respiration rates. It keeps fruits and vegetables fresh for longer without manual monitoring.

4. Cryogenic Reefer

Used for ultra-low temperatures, often relying on liquid nitrogen or carbon dioxide instead of compressors. You’ll often find these in the medical and biotech industries.

5. Diesel-Powered Reefer

Some containers come with built-in diesel generators for routes without access to shore power. They’re ideal for long inland legs or remote delivery points.

Why Reefer Containers Matter in Global Trade

Global food and pharmaceutical supply chains depend heavily on refrigerated reefer containers. Without them, products like vaccines, seafood, and fresh produce couldn’t travel thousands of miles without losing quality.

Each shipment is part of what’s known as the cold chain, a network of temperature-controlled storage and transportation that prevents spoilage and waste. Even a brief temperature spike can ruin an entire shipment, which is why precision and monitoring are everything.

At Nissin Belgium, reefer shipments are constantly tracked, monitored, and supported by trained logistics teams who understand the sensitivity of every degree.

Before You Ship: What Shippers Should Know

If you’re planning to ship temperature-sensitive goods, here are a few key points to remember:

1. Pre-cool your products before loading. Reefer units maintain temperature but are not designed to freeze or chill cargo from room temperature.

2. Load correctly by allowing airflow gaps and avoiding overpacking.

3. Match your settings for temperature, humidity, and ventilation to the cargo’s needs.

4. Monitor continuously. Many reefers send live data to logistics teams for real-time visibility.

Following these steps keeps goods fresh and reduces the risk of costly spoilage.

The Role of Experienced Freight Forwarders

Using reefer containers effectively isn’t just about the technology. It’s about coordination, timing vessel schedules, verifying customs documents, and maintaining the right temperature from door to door.

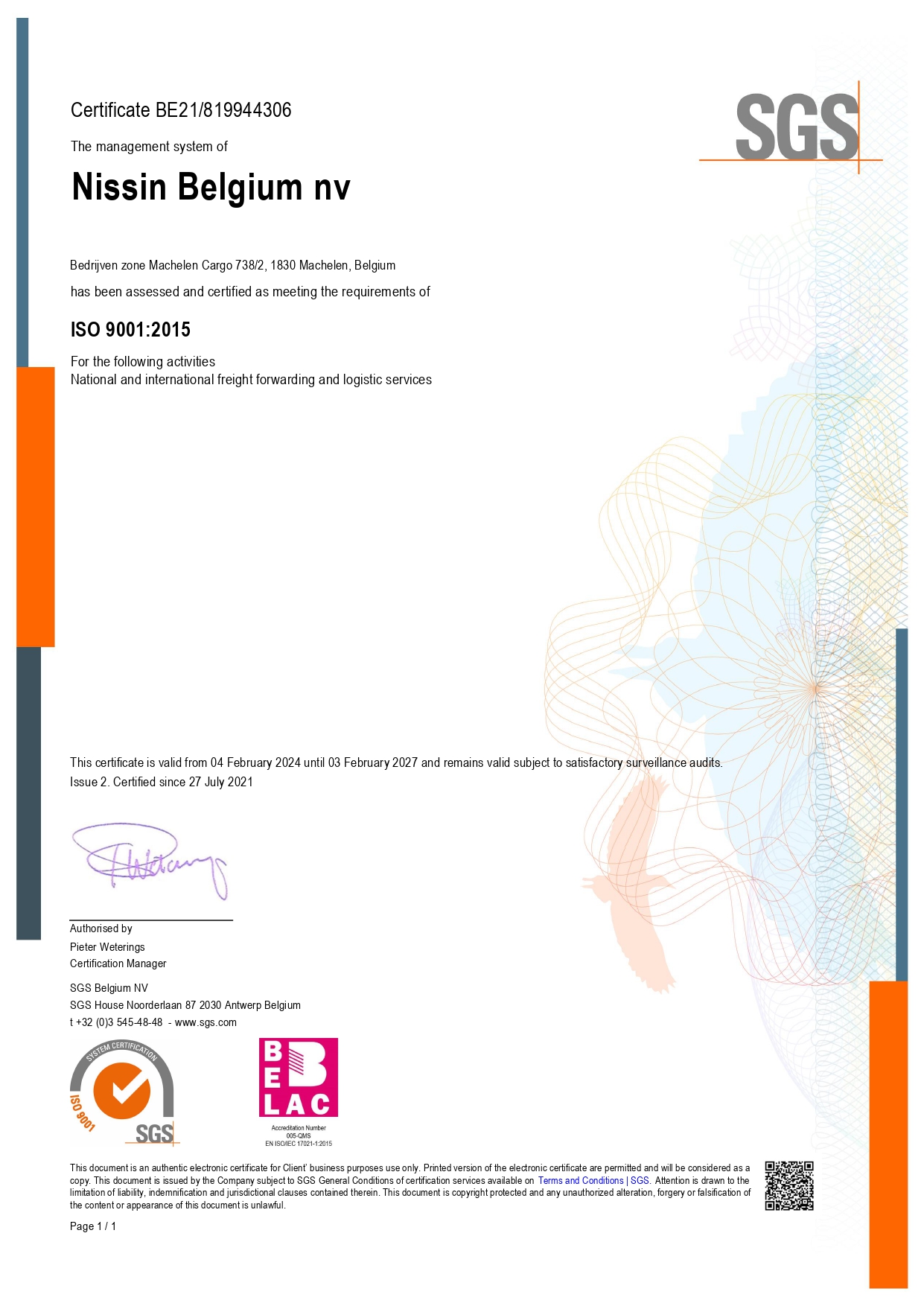

That’s where experienced logistics providers like Nissin Belgium come in. Our reefer operations cover everything from booking and container inspection to temperature tracking and cargo handoff. With decades of experience in temperature-controlled shipping, we assure your products travel safely from origin to destination.

Ship with Confidence Through Nissin Belgium

Shipping temperature-sensitive goods requires more than a booking; it needs expertise.

Learn more about refrigerated shipping options through Nissin’s Ocean Freight Services. Our team is ready to assist you. Please call +32 2 751 44 99 or email HowCanIHelpYou@be.nissin-eu.com for prompt and professional support.