What Are the top 5 Methods of Storing Goods in a Warehouse?

Efficient warehousing is the backbone of modern logistics. It’s not just a place to keep goods; it’s where supply chain strategy comes to life. From keeping food fresh to organizing electronics or managing thousands of online orders, every product needs a smart storage plan. The right system can reduce waste, cut costs, and make deliveries faster.

Let’s look at five major methods of storing goods in a warehouse and what makes each one effective for different industries and product types.

Pallet Racking Systems: Organized, Scalable, and Space-Smart

Walk into any large warehouse and you’ll see rows of pallets stacked high. This is pallet racking in action. It’s the most widely used storage method because it combines structure and flexibility.

Pallets are loaded with goods and placed on steel racks, ready for forklifts to pick or move. The system can adapt to almost any product size and quantity, making it ideal for retailers, manufacturers, and distributors.

Here’s the thing: not all racks are built the same.

1. Selective racking gives you access to every pallet easily.

2. Drive-in racking works best for bulk items that move out in groups.

3. Push-back and flow racking are smart options when you need first-in-first-out or last-in-first-out systems.

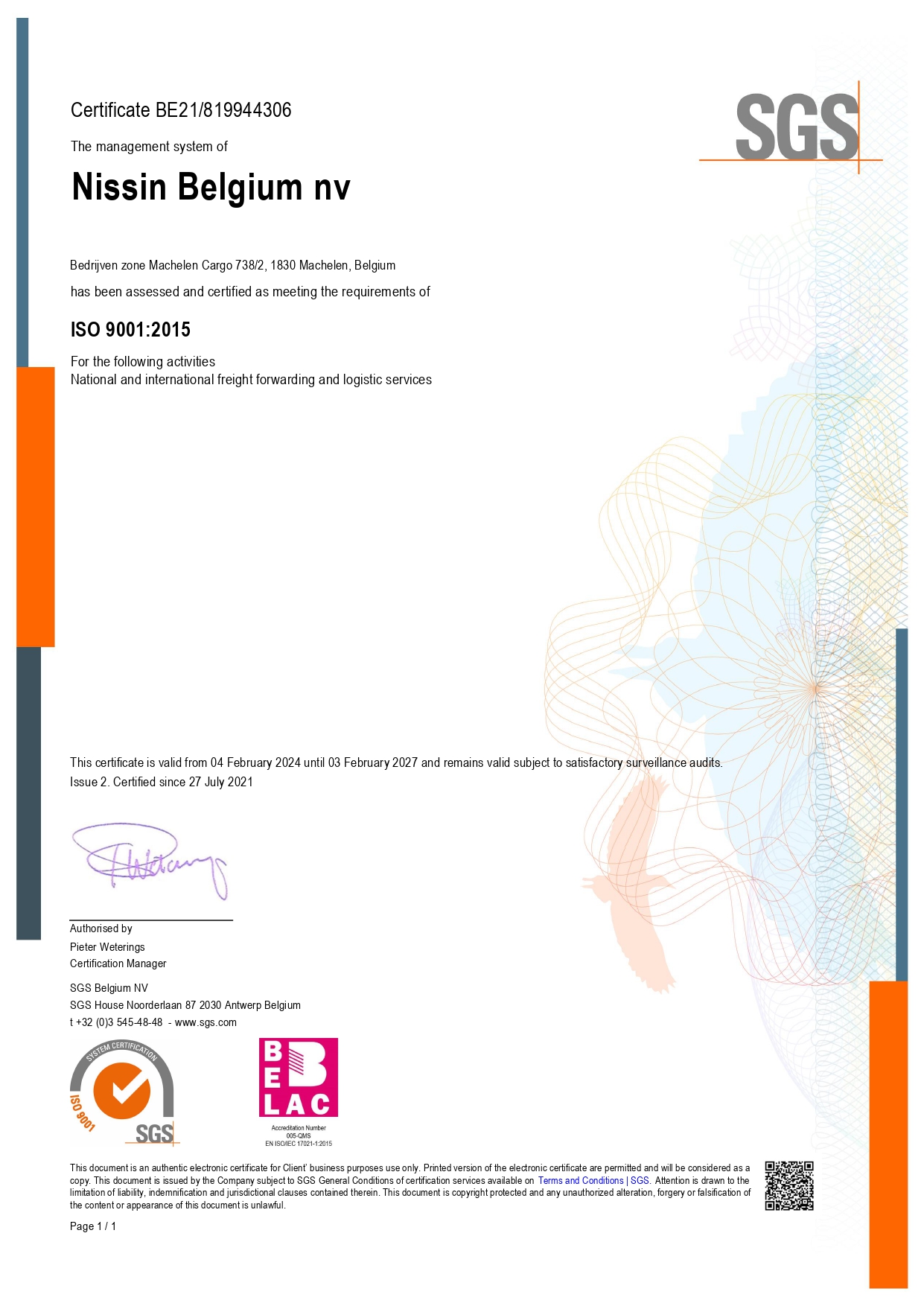

Pallet racking makes every cubic meter of your warehousing space count. If your operations are expanding and you’re looking for optimized pallet or bulk storage, Nissin Belgium offers flexible options designed to maximize capacity and reduce handling time. Explore Nissin’s warehousing solutions here.

Shelving and Bin Storage: Perfect for Small and Fast-Moving Items

When the products are light, small, or need to be hand-picked, shelving and bin storage are the go-to systems. You’ll find this setup in e-commerce centers, pharmacies, and automotive parts warehouses.

Unlike large racks, these systems are built for accessibility. Workers can quickly grab what they need without machinery.

1. Static shelving works for slow-moving inventory that stays put for a while.

2. Mobile shelving saves floor space and moves on tracks for better density.

For businesses that depend on speed and order accuracy, combining racking with bin storage keeps operations smooth.

Mezzanine Storage: Build Up, Not Out

When the warehouse floor fills up, smart companies go vertical. Mezzanine storage adds an extra layer of space by creating an elevated platform or partial second floor.

This system is especially handy for fast-growing businesses that want to expand capacity without relocating. A mezzanine can hold shelves, packing stations, or even light machinery.

Think of it as an internal balcony for your warehouse, turning unused airspace into profitable storage. For distribution or retail hubs, mezzanine setups can drastically improve organization without major construction costs.

Temperature-Controlled Storage: Protecting Sensitive Goods

Some products simply can’t sit on a standard rack. Medicines, dairy, cosmetics, or fine chemicals all need specific temperature and humidity conditions. That’s where specialized warehousing for temperature-sensitive products comes in.

This category includes:

1. Cold storage for frozen or refrigerated goods

2. Chilled storage for items that need cool but not freezing conditions

3. Ambient storage for goods requiring steady room temperature

Temperature-sensitive warehousing uses insulation, humidity monitors, and real-time temperature tracking to maintain consistent conditions. Many facilities even have backup generators to prevent spoilage during power cuts.

Nissin Belgium offers reliable temperature-sensitive warehousing with strict climate monitoring and backup systems, helping industries like pharmaceuticals and food logistics maintain safety and quality across long supply chains.

Automated Storage and Retrieval Systems (AS/RS): The Future of Warehousing

Now imagine robots doing the heavy lifting. Automated systems use conveyors, cranes, and robotic shuttles to place and move goods faster than manual processes.

Automation isn’t science fiction anymore. It’s real, scalable, and efficient. It minimizes human error, improves safety, and provides real-time inventory visibility.

For large distribution hubs, AS/RS systems save both time and space while keeping stock levels accurate to the last unit.

Why the Right Method Matters

Every business has unique storage needs. The products you handle, turnover rate, and environmental factors all determine which system fits best. Often, warehouses combine several methods to balance space efficiency and accessibility.

For example, a food logistics company might use pallet racking for packaged goods, shelving for small items, and specialized warehousing for temperature-sensitive products for perishables. Nissin Belgium’s experts can help you plan a hybrid system that fits your product categories, reduces waste, and keeps distribution smooth.

Nissin Belgium: Your Reliable Warehousing Partner

At Nissin Belgium, warehousing is more than just storage. It’s about control, safety, and service. Our facilities are equipped for both general cargo and temperature-controlled goods, designed to support manufacturers, distributors, and retailers across Europe.

From storage and warehousing services to value-added logistics like labeling, picking, and distribution, every part of their process is built for dependability. Need advice or a quote? Our logistics team is just a call or email away.

Our team is ready to assist you. Please call us at +32 2 751 44 99 or email your requirements to HowCanIHelpYou@be.nissin-eu.com for prompt and professional support. Or visit Nissin Belgium Warehousing to explore flexible storage solutions for your business.