Understanding the Role of Warehousing in Lithium Battery Storage and Distribution

The global demand for lithium batteries is climbing rapidly as electric vehicles, renewable energy systems, and portable electronics continue to expand. While production and technology are crucial, the backbone of smooth supply lies in warehousing and distribution. Handling these batteries is not the same as handling standard cargo. They fall under the category of dangerous goods, and improper management can lead to serious risks. That is why lithium ion battery shipping requires specialized facilities, strict safety protocols, and professional logistics services.

Let’s break down the role warehousing plays in keeping these sensitive goods safe while maintaining an efficient global supply chain.

Why Lithium Batteries Need Specialized Warehousing

Lithium batteries are classified as dangerous goods because they can overheat, catch fire, or even explode if mishandled. Warehouses that handle them need more than just storage space. They require:

1. Temperature and humidity control to prevent instability.

2. Fire suppression systems designed to deal with lithium-related incidents.

3. Dedicated storage zones that separate batteries from incompatible goods.

4. Trained personnel who understand how to handle, label, and monitor these products.

These measures reduce the risks linked to lithium ion battery shipping and create a controlled environment that aligns with international transport regulations.

The Connection Between Warehousing and Shipping

For most manufacturers, the journey of batteries does not end at the factory. Once produced, they need to move across borders through the import of goods process. At this stage, warehouses act as the link between production sites, customs authorities, and distributors.

Well-organized warehouses streamline:

1. Inspection and documentation to confirm compliance with international shipping standards.

2. Consolidation of cargo to reduce costs and improve efficiency.

3. Staging areas where goods are prepared for air, sea, or road transport.

Without reliable warehousing, lithium ion battery shipping would face delays, increased risks, and higher costs.

Safety Protocols in Lithium Battery Warehousing

The foundation of safe storage lies in strict safety protocols. These are not optional—they are required for legal compliance and public safety. Some of the most common practices include:

1. Segregation of stock: Different types of batteries are stored separately to prevent cross-contamination or accidental interaction.

2. Monitoring systems: Sensors track temperature, humidity, and gas emissions around the clock.

3. Emergency response plans: Teams are trained to act quickly in the event of fire, leakage, or structural damage.

4. Compliance with international regulations: Guidelines such as IATA and IMDG codes guide safe logistics services for air and sea transport.

When warehouses apply these protocols, the risks associated with handling dangerous goods are kept under control.

Role of Logistics Services in Distribution

Once batteries leave the warehouse, logistics services take over to distribute them globally. Here, warehousing and logistics work hand in hand. Warehouses prepare the goods, while logistics networks handle:

1. Transportation planning based on destination and mode of travel.

2. Documentation for customs clearance during the import of goods.

3. Last mile delivery to manufacturers, resellers, or end-users.

This collaboration keeps supply chains reliable and efficient. Given the rising demand for electric vehicles and renewable energy storage, such logistics support is more critical than ever.

The Impact of Regulations on Warehousing and Shipping

Governments worldwide have recognized the risks tied to lithium batteries. As a result, regulations on lithium ion battery shipping are strict and evolving. Warehouses must stay updated with:

1. Labeling requirements for dangerous goods.

2. Packaging standards that reduce fire or shock risks during transit.

3. Customs procedures during the import of goods.

Companies that fail to follow these rules risk fines, shipment delays, and damaged reputations. Warehousing partners with regulatory expertise help businesses avoid these pitfalls.

The Importance of Global Distribution Hubs

Not all warehouses can manage dangerous goods, which makes specialized hubs invaluable. These hubs serve as central points where batteries are stored, inspected, and distributed. By working with warehouses equipped for dangerous goods, companies gain access to:

1. Safe storage compliant with international standards.

2. Faster clearance processes during cross-border shipments.

3. Reliable partnerships for long-term distribution strategies.

This level of support is especially important for manufacturers expanding into new markets.

Conclusion

The role of warehousing in lithium battery distribution goes far beyond providing storage space. It combines risk management, compliance, and logistical coordination to keep supply chains efficient and safe. From monitoring conditions in storage to coordinating with logistics services for global distribution, warehouses are central to the success of lithium ion battery shipping.

As industries continue to grow, so does the need for professional handling of dangerous goods. Companies that want to thrive in international trade must work with partners who can manage the import of goods with precision and care.

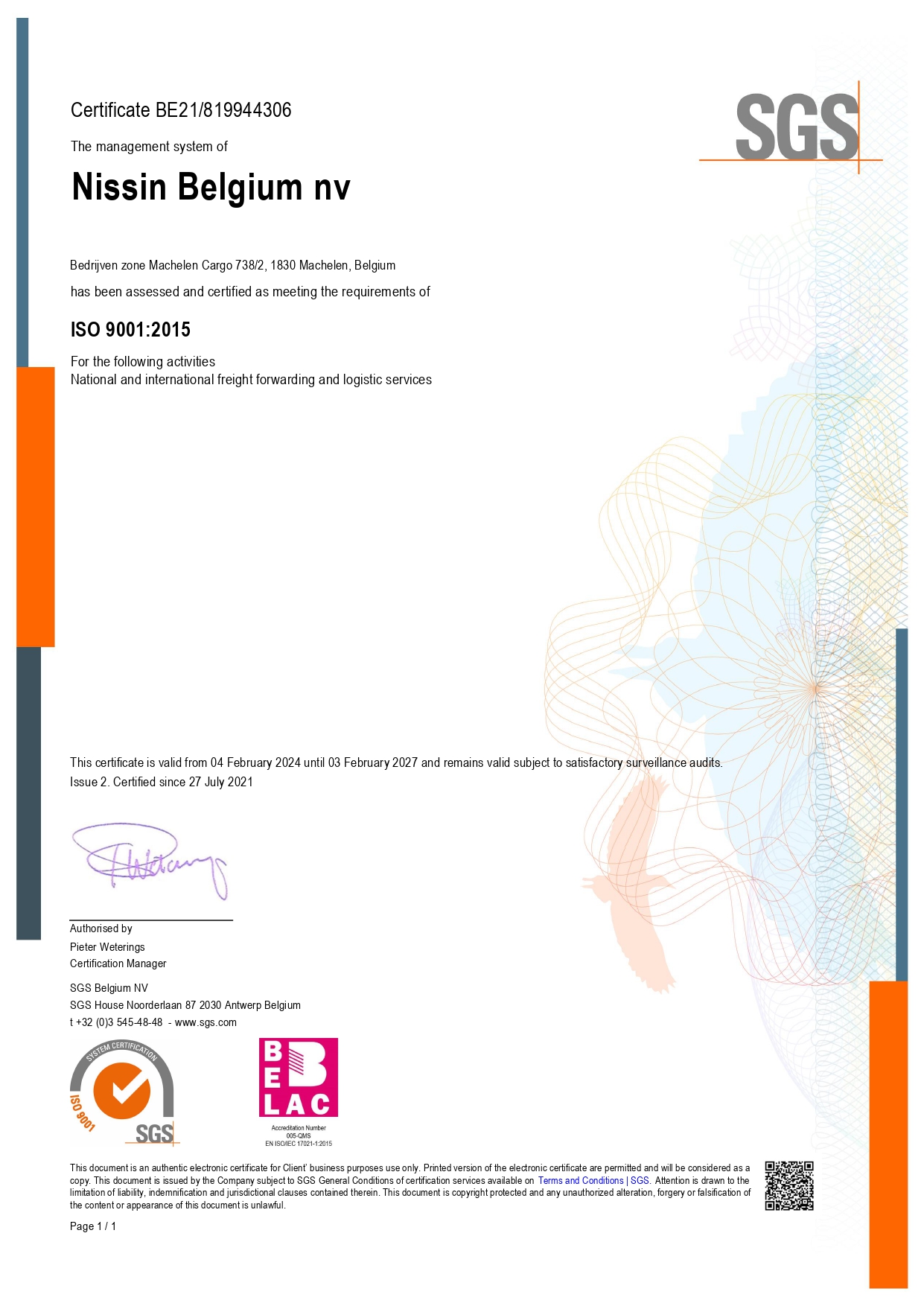

If you are seeking a trusted partner in lithium battery warehousing and distribution, Nissin’s LIB Village offers the expertise and infrastructure you need. Our team is ready to assist you—please call us at +32 2 751 44 99 or email your requirements to HowCanIHelpYou@be.nissin-eu.com for prompt and professional support.