Lithium-Ion Battery vs Polymer Battery: What Logistics Providers Need to Know About Handling and Safety

Battery-powered devices dominate global trade today. Phones, electric tools, medical devices, drones, and even small appliances all depend on compact power sources. For logistics teams, this means one thing. Handling, packaging, and moving batteries has become a core part of daily operations. Understanding how these batteries behave is no longer optional.

One of the biggest topics that comes up during lithium ion battery shipping is the debate surrounding lithium ion battery vs polymer battery. Many shippers assume both types behave the same, but their structure, casing, and performance lead to different handling needs. Knowing these differences helps logistics providers reduce safety risks and manage compliance across international routes.

What Makes These Batteries Different

A traditional lithium ion battery is built with a liquid electrolyte inside a sturdy metal case. This design supports higher energy density, which is why laptops, power tools, and industrial handheld equipment rely on it.

A lithium ion polymer battery uses a gel or solid electrolyte inside a flexible pouch. This design is lighter, thinner, and easier to shape. Think smartphones, tablets, drones, and wearable tech. The pouch allows compact design, but it also reacts differently to heat, pressure, and physical stress.

When comparing lithium ion battery vs polymer battery, the key difference lies in their structure. One is rigid and protected. The other is flexible and lightweight. Both store lithium-based energy, but their behavior during transit varies.

Why Logistics Providers Need to Understand This

During transport, batteries face vibration, stacking pressure, temperature swings, and occasional rough handling. Each battery type tolerates these conditions differently.

A rigid lithium ion battery can handle external pressure better, but if internal heat builds up, the casing traps it. A polymer pouch battery may not trap heat the same way, but its thin casing is more prone to swelling, deformation, or puncture.

If you’re operating regional or global routes, the type of battery determines:

Packaging choices

1 State of charge during shipping

2 Labeling requirements

3 Routing options for air, sea, or ground

4 Storage rules inside facilities

This is why understanding a basic lithium ion polymer battery structure helps reduce mistakes and streamline compliance.

Key Safety Points for lithium ion battery shipping

Regardless of type, the risks during movement remain similar. These are the main challenges logistics teams need to be aware of:

1 Short circuits caused by exposed terminals

2 Thermal runaway triggered by heat, damage, or defective cells

3 Swelling in pouch-style polymer batteries

4 Mislabeling of UN classification

5 Incorrect packaging during international freight

6 Excess charge during air transport

Each point brings potential disruption, but proper training and process can control these risks.

Packaging Rules You Can’t Ignore

Good packaging makes or breaks safe battery transport. Here’s what applies to both chemistries:

1 Use strong outer packaging that can withstand drops and vibration

2 Add internal cushioning to prevent movement

3 Keep batteries from touching one another

4 Cover terminals with non-conductive material

5 Label according to transport mode (air, sea, or road)

6 Follow UN 38.3 testing requirements

Polymer pouch batteries need extra care with compression. Avoid placing heavy items above them, and use packages that prevent bending.

Managing Heat and Charge Levels

Lithium-based batteries react strongly to heat. Storage areas should remain cool with proper ventilation. During air transport, batteries usually must be shipped at no more than 30 percent state of charge. This rule applies across chemistries because lower charge means less stored energy, reducing the chance of runaway.

For warehouse teams, simple routines like checking temperature, inspecting packaging on arrival, and monitoring charge levels can avoid problems later.

Handling Damaged Batteries

If a lithium ion battery shows dents, cracks, or leakage, it must be isolated immediately. For a lithium ion polymer battery, swelling is the red flag. A swollen pouch can expand like a pillow. Any sign of bubbling or soft spots means the cell is unstable.

Damaged batteries should be placed in fire-resistant containers and moved away from operational zones. Staff must report incidents early so corrective action can start right away.

Documentation Matters as Much as Packaging

During lithium ion battery shipping, documentation errors cause more shipment delays than battery faults. Missing UN numbers, incorrect classification (UN3480 vs UN3481), or incomplete Shipper’s Declarations can stop cargo from flying or even trigger compliance penalties.

Logistics teams need updated knowledge of IATA DGR, ADR, and IMDG rules. Regulations shift often, and new battery sizes or designs appear every year. The more accurate your paperwork, the smoother your route.

Why Choosing the Right Logistics Partner Is Crucial

Battery logistics isn’t just about packing and labeling. It involves storage, routing planning, compliance knowledge, and risk control. Many companies moving electronics or industrial gear rely on specialists to handle their lithium ion battery shipping because errors can interrupt global supply chains.

A reliable partner understands the full picture. They know how to classify batteries, prepare documents, handle emergency situations, and manage multimodal movements without unnecessary delays.

What This Means for the Future of Battery Transport

Demand for lightweight power systems is rising fast. The popularity of a lithium ion polymer battery in consumer electronics will keep increasing. Electric mobility, drones, medical technology, and smart devices all depend on safer and lighter energy sources.

With this growth comes more responsibility for freight providers. Understanding lithium ion battery vs polymer battery differences helps teams prevent incidents, keep shipments compliant, and support clients that rely on safe and precise logistics.

The more informed your operations are, the easier it becomes to move these products confidently across global networks.

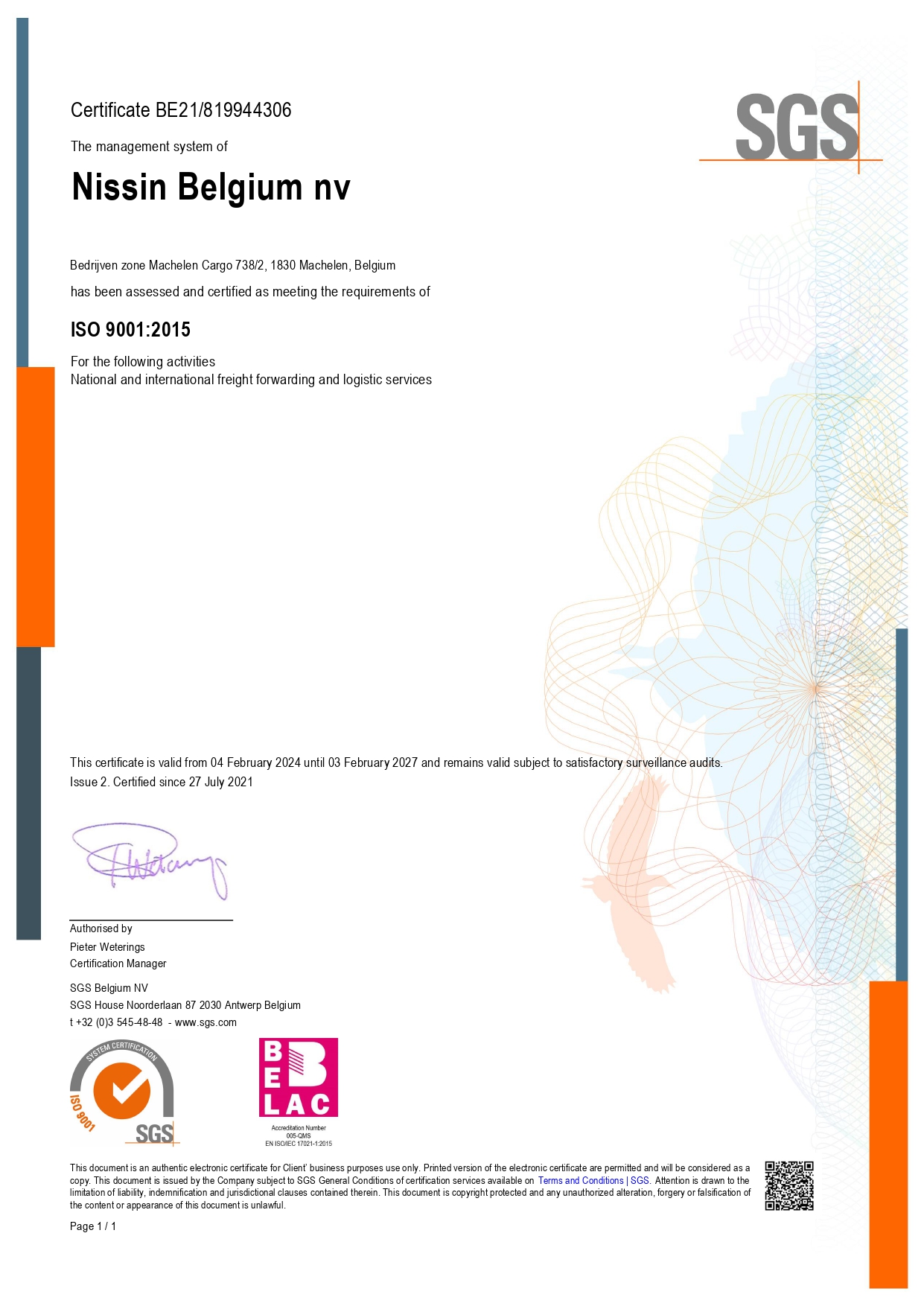

If you transport lithium-based batteries and want a partner who understands every step of the process, Nissin Belgium’s LIB Village is built to support your needs.

Our team is ready to assist you. Call +32 2 751 44 99 or email HowCanIHelpYou@be.nissin-eu.com for prompt and professional support.